| |

| |

| This is not a crusher, but a granulator.

Our GranCutter granulator provides you with top-quality recycled materials, and

it have a good reputation among the users. The 21st century is a generation of

recycling. Please try and see the effect of GranCutter swing and press cutting

system. | |

| Comparison with current granulators |

|

Much less dust | The

blade does not cut through material twice. This minimizes the amount of dust,

static electricity and heat. | |

Very few miss-cuts | The

spacing between the blades approximately duplicates the size of the original material

pellets, so sprues and runners get granulated to roughly the same dimension. There

are very few miss cuts. | |

Very quiet | Cutting

is held to a minimum, thus the machine is very quiet. | |

Very easy to clean | Because

there is minimal static electricity produced, and dust created doesn't adhere

to interior surfaces. Moreover, two large panel doors open downward to afford

greater cleaning convenience, and, ultimately, significantly shorten cleaning

time and downtime. (Average cleaning time: 5-7 minutes) | |

Soft materials acceptable | With

the SPC-S Series Grancutter, previously incompatible soft materials can now be

granulated. |

|

| Conventional Granulators |

Conventional

rotary cutter granulators. when cutting sprues and runners that are larger than

the cutter height, leave pieces in a comb-like form.(See fig.1). The remaining

pieces, held in the cutters, inhibit the cutting of subsequent sprues and runners

and runners, and, while trapped, get repeatedly shaved into dust. In the case

of thin sprues and runners, cut pieces remain in a ring-like form on the stationary

cutters. (See fig. 2). Conventional

rotary cutter granulators. when cutting sprues and runners that are larger than

the cutter height, leave pieces in a comb-like form.(See fig.1). The remaining

pieces, held in the cutters, inhibit the cutting of subsequent sprues and runners

and runners, and, while trapped, get repeatedly shaved into dust. In the case

of thin sprues and runners, cut pieces remain in a ring-like form on the stationary

cutters. (See fig. 2).

Those pieces cannot be processed until the next sprues

and runners are added. While caught, they are also rubbed to dust.

|

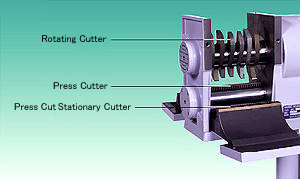

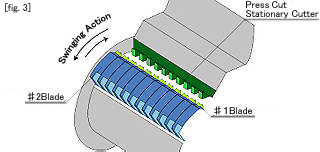

| The

Grancutter | |  he

Grancutter utilizes a cam-driven swinging shaft rather than a rotating blade.

The patented system cuts the sprues and runners between teeth on the swinging

Shaft and teeth on a stationary blade mounted on the interior frame of the Grancutter.

(See fig. 3). he

Grancutter utilizes a cam-driven swinging shaft rather than a rotating blade.

The patented system cuts the sprues and runners between teeth on the swinging

Shaft and teeth on a stationary blade mounted on the interior frame of the Grancutter.

(See fig. 3).

When the swinging press cutter converges on the stationary

cutter, the sprues and runners are cut in the "bite" of the teeth, and

the granules are ejected from between the teeth of the cutters. The press cutter

swings open again, and the next sprues and runners fall between the teeth to be

cut. (See sequence of photos). There are no trapped pieces of sprues and runners,

thus no dust. There is also very little static electricity or heat produced

|

| The

Mechanics of the Grancutter | |  In

the case of cylindrical sprues and runners(See fig.4), the first blade of the

swinging press cutter cuts the bottom half, then the sprue or runner is cut lengthwise

by the second blade. The top half of the sprue or runner, as shown in fig.5, remains

above the blades. It fall between the teeth when the press cutter swings open

for the next " bite", and is then cut into granules. The result is that

the sprues and runners are thoroughly and reliably cut, not shaved into dust or

left uncut. In

the case of cylindrical sprues and runners(See fig.4), the first blade of the

swinging press cutter cuts the bottom half, then the sprue or runner is cut lengthwise

by the second blade. The top half of the sprue or runner, as shown in fig.5, remains

above the blades. It fall between the teeth when the press cutter swings open

for the next " bite", and is then cut into granules. The result is that

the sprues and runners are thoroughly and reliably cut, not shaved into dust or

left uncut.

With

conventional granulators that are equipped with a screen, sprues and runners that

are smaller than the mesh can drop into the material tank without being cut. Miscuts

can occur. With the Grancutter system, however, because pieces of sprues and runners

remain above the blades if they are uncut, they cannot fall into the material

tank without being granulated. Furthermore, the sprues and runners are cut at

a right angle to the swinging shaft and are discharged between the teeth, Therefore,

there is nearly no erroneous cutting. With

conventional granulators that are equipped with a screen, sprues and runners that

are smaller than the mesh can drop into the material tank without being cut. Miscuts

can occur. With the Grancutter system, however, because pieces of sprues and runners

remain above the blades if they are uncut, they cannot fall into the material

tank without being granulated. Furthermore, the sprues and runners are cut at

a right angle to the swinging shaft and are discharged between the teeth, Therefore,

there is nearly no erroneous cutting.

|

With the SPC-S series Grancutter, it is now

possioble

to granulate soft-type resin sprues

and runners that could not be recycled. |

|  SOFT

TYPE GRANCUTTER SPC II-S Series] SOFT

TYPE GRANCUTTER SPC II-S Series]

SPCII-400S SPCII-400S

SPCII-750S SPCII-750S |

| The

soft-type Resin Grancutter | | End-users have repeatedly

expressed a concern that they could not recycle various elastomers and soft-type

resins that they use, and they wished there was a machine to granulate sprues

and runners of those materials for re-use. Until now, there was basically no way

to recycle elastomers and soft-type resins,and it was impossible to satisfactorily

use the discarded sprues and runners. In response, Harmo-Soken has developed the

SPC-S Series Grancutter, designed specifically to granulate those materials for

recycling. The significant difference of the SPC-S Series machines relative to

the SPC Series Grancutters is the clearance in the "bite" of the teeth.

Whereas the space between the "biting" teeth on the normal-material

machines is approximately 0.4mm, the gap on the SPC-S Series machines is under0.03mm.

If the gap is any larger, PP sprues and runners are stretched, not cut, and soft

elastomers are torn, not cleanly granulated. Due to this precision, the machine

must not be used for granulating materials other than those soft-type materials

specifically designated as compatible. |

Some examples of suitsble materials.

SPC-S SERIES

(For SOFT materials) |

|  |  |  |

Polypropylene

Pic | Polyethylene

Pic | Thermoplastic

Elastomer

Pic | Polyurethne

Pic |

|  The

Soft-type Resin Grancutter should not be used for Normal and Hard Materials. The

teeth are not designed to cut those materials, and damage to the machine occurs.

Do not attempt to granulate Normal and Hard Materials in the S-Series Grancutter.

Harmo-Soken is not responsible for any damage resulting from incompatible material(Normal

and Hard materialsÛjbeing granulated. The

Soft-type Resin Grancutter should not be used for Normal and Hard Materials. The

teeth are not designed to cut those materials, and damage to the machine occurs.

Do not attempt to granulate Normal and Hard Materials in the S-Series Grancutter.

Harmo-Soken is not responsible for any damage resulting from incompatible material(Normal

and Hard materialsÛjbeing granulated. |

|

| Movie |

Click image or title to see motion image.

| QuickTime

Movie | GIF

Animation | GIF

Animation |  |  |  |

| A total image of each different

blade moving in one continuous sequence, including overall movement of a rotary

blade and close-up of a moving blade. Also you find the casing is wide open for

easy cleaning. | Overall image of

a rotary blade with bigger image size. | Close-up

image of a moving blade actually cutting materials into small pieces with bigger

image size. | |

QuickTime 3 or 4 required

Length:42sec.

Image size : 160 * 120

File size : 717KB |

Length:Endless

Image size : 269* 215

File size : 345KB |

Length:Endless

Image size : 250* 190

File size : 530KB |

|

|

| |